Along with the development of industrialization and modernization of the society, the demand for industrial pumps is more and more widespread. Industrial pumps play an important role in production operations as well as living in service buildings, manufacturing plants, mineral mines ... So you already know how to choose industrial pumps based on parameters. Necessary techniques yet? Let's find out with Dai Nam!

- Flow to be pumped by industrial pumps

Lưu lượng nước là lượng nước chảy qua mặt cắt ngang sông trong một đơn vị thời gian. Lưu lượng của máy bơm nước là lượng nước mà máy bơm có thể vận chuyển được trong một đơn vị thời gian.

The common unit of pump flow is: m3 / h, l / s, l / min or GPM ... .. The flow rate of the pump will be calculated by the design engineers based on many criteria to meet the requirements. demand. Therefore, when buying a pump, it is necessary to choose the pump with the minimum flow rate that meets the design given by the design and pay attention to the measuring unit of flow to choose the most optimal pump type.

Determining the required pump volume is very important in choosing an industrial pump

- Total propulsion height (head push) of industrial pumps

The total propulsion height of the pump is the sum of the height of the water the pump push is calculated from the lowest point of the water surface to the highest point to be pumped vertically and the pressure loss on the elbow , friction due to pipe wall and pressure loss when pump is overloaded. If there are multiple outlets, select the longest water pipeline from the pump position to calculate the highest pressure loss.

The formula for calculating the Total push height (push head) of an industrial pump is as follows:

H = H1 + H2 + H3

H1: is the sum of the highest head (ie the height of the water push by the height from the pump location to the farthest place of the system)

H2: head to spray water at the outlet.

H3: pressure loss at pipelines (local loss) and pipeline friction.

The unit for measuring the pushing height (push head) such as: mH20, bar, Psi, Kpa,….

After calculating the total head of push, need to multiply the factor of safety to find the head of the pump to be selected.

Therefore, when buying a pump, you need to provide this information so that the supplier can choose and advise the right type.

- Pump capacity:

- Pump power is the power consumed to generate flow Q and pressure height H, measured in kW or HP. (1HP = 0.75kW)

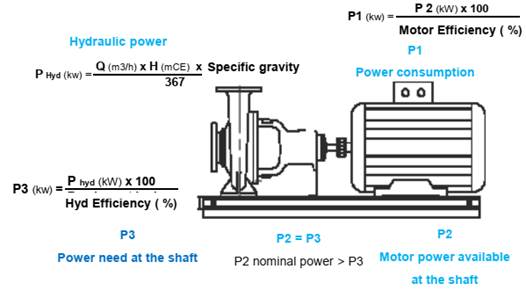

- Types of pump capacity when calculating to choose:

- Useful power: is the energy that the pump consumes to boost a liquid (water).

- Axial capacity of axial power pump): This is the power to compensate for the energy lost due to friction in the shaft, characterized by the utility coefficient. This capacity may vary due to pump performance by different manufacturers.

- Motor power: The motor consumes more energy than the pump because the energy transferred from the motor to the pump is partly lost due to the motor work, the transmission between the motor shaft and the pump, due to friction on shaft.

- The formula for calculating the pump's capacity is as follows:

Capacity is an indispensable parameter when choosing an industrial pump

Finally, once you have grasped the basic parameters to choose a pump, choosing the most suitable and optimal pump in terms of quality, price also needs to consider brand and origin factors. origin of the goods. Besides technical support, after-sales service is an important factor showing the capacity of the pump supplier.

You should choose a reputable brand, good after-sales service such as warranty and genuine spare parts to use with peace of mind.

Instructions for installing and operating industrial pumps of engineers Dai Nam Company

DAI NAM Company with over 15 years of experience in the field of supplying industrial pumps , is the General Distributor of brand name pumpsMASFLO - Pháp tại Việt Nam. Với sự nỗ lực không ngừng nghỉ của tập thể cán bộ, nhân viên của công ty Đại Nam, sản phẩm bơm MASFLO- Pháp đã được các chủ đầu tư tin dùng và có mặt ở hầu hết các tỉnh thành, góp phần thúc đẩy sự phát triển – tăng cường tính an toàn cho các công trình.

For more information please contact:

DAI NAM SCIENCE INDUSTRIAL JOINT STOCK COMPANY

Address: Room 303- 3rd floor, AN BINH mixed building 1- Number 3 Tran Nguyen Dan street-Dinh Cong new urban area- Dinh Cong ward - Hoang Mai district - Hanoi.

Hotline : 0383 478 272 Tel : 024 364 00111

Email: dainam@dainamco.vn Website: congnghiepdainam.com.vn