After a period of use, usually 1 to 2 years, large capacity industrial pumps used in high-rise buildings, factories ... for fire protection, water supply and drainage, air conditioning ... need to Perform pump maintenance. Effective pump maintenance allows the pump to be in good working order, while at the same time detecting problems in time to plan repairs and avoid pump failures ahead of time. Periodic maintenance will detect a decrease in efficiency and reduced flow, which will occur in the long run before the water pump fails.

Establishment of a water pump system maintenance process includes the following factors:

• Security Activities

• Predictive activities

• Periodically check the effectiveness

Most maintenance work can be divided into either protective or predictive work. Preventive maintenance is a constant need such as lubricating the engine, periodically adjusting, and removing residue. Predictive maintenance focuses on checking under reduced pump performance.

- Preventive maintenance works: including engine lubrication, coupling adjustment, seal maintenance and joint replacement. Mechanical seal must be checked periodically to ensure that there is no leak or such leak must comply with permitted technical standards. Leakage mechanical seals that exceed technical specifications must be replaced. However, the magnitude of the leak is required to lubricate and cool the solid seal, but the filament needs to be adjusted if the leak exceeds the manufacturer's specifications. Fear of the hut to be replaced if it tightens beyond the leak. Tightly tightened filament causes unnecessary wear on the pump shaft or coupling wear and increases electrical output. Regular maintenance of the pump engine, such as lubricating or cleaning the engine, is also important.

- Predictive work: helps to minimize unexpected equipment downtime. Called "condition assessment", or "condition control", it becomes much faster than modern testing. This method is applied to the pump system as follows:

Analysis of oscillation.

+ Analysis of lubricating oil for the machine

+ Check performance periodically.

+ Check water performance

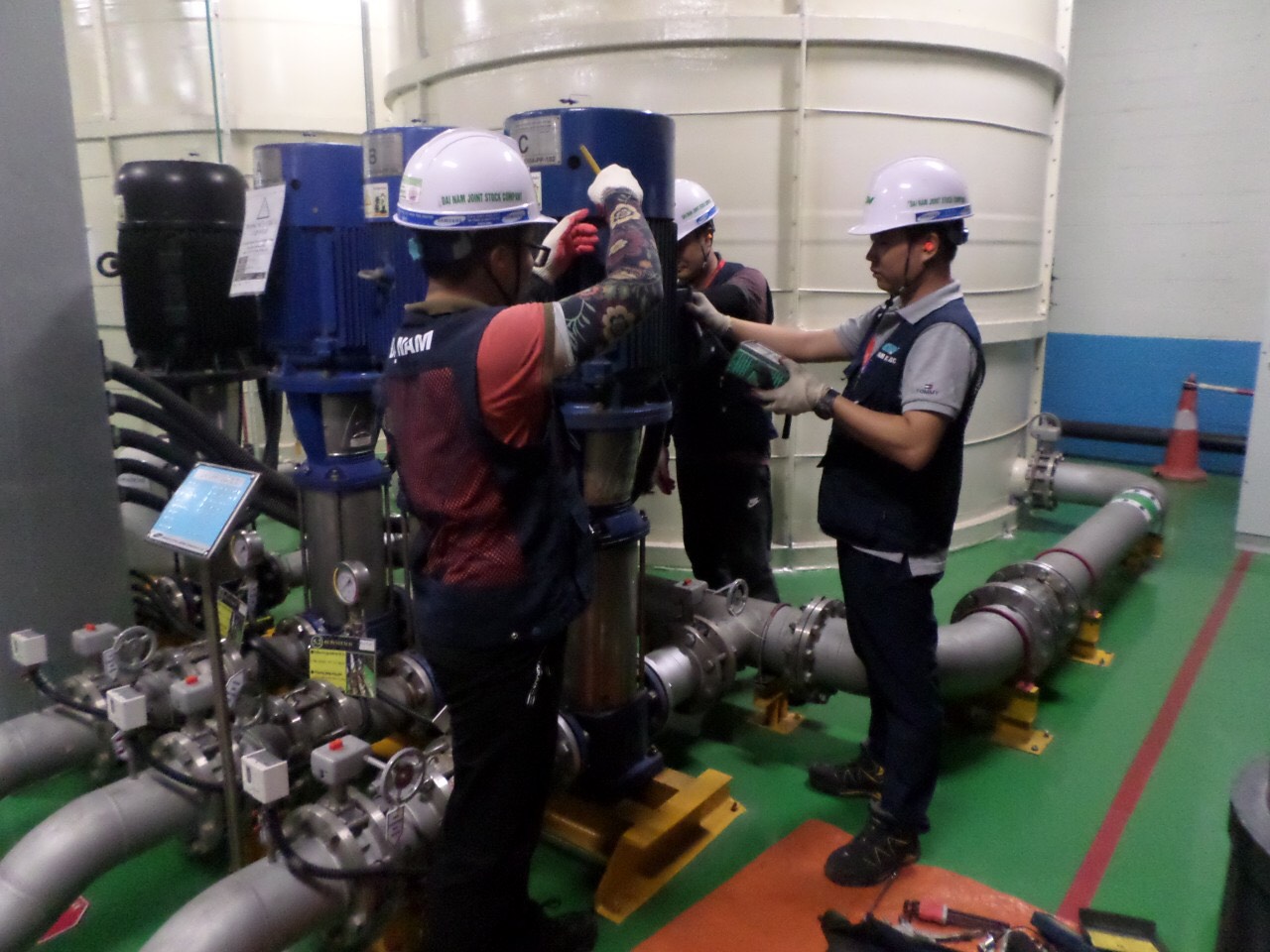

Maintenance of industrial pumps must be performed by skilled technicians with expertise and long-term experience, otherwise it will cause additional losses after disassembly.

Dai Nam is a unit with a team of skilled technicians, experienced and knowledgeable about industrial pumps and valves, always having proper installation, operation, maintenance and maintenance plans and overcoming them. An incident occurred. Please contact us for the best support.

Hotline: 098 678 4306

Email: dainam@dainamco.vn

Below are some pictures of the technical team of Dai Nam company performing the maintenance and maintenance process at Samsung Bac Ninh and Samsung Thai Nguyen factories.