Working principle of centrifugal pumps

Centrifugal pumps are the most commonly used water pumps in industry. Centrifugal pumps are used to generate flow or increase pressure of liquids, including two types: vertical centrifugal pumps and horizontal centrifugal pumps. Both types of pumpswork in the same way and are fairly simple involving the suction and the pushing process.

The part that does this is the impeller - the most important part of the water pump.

Push process:

The impeller is a series of curved blades fitted inside the closed disc. The impeller is always submerged in water. When rotating, it causes the surrounding liquid to move. It creates centrifugal force for the water particles in the impeller to be thrown out and move along the channels that enter the thrust tube with greater pressure.

.png)

H1: Water after moving the impeller is collected and moved along the flow.

Suction process:

Simultaneously with the pushing process, at the entrance of the impeller creates a vacuum zone and under the effect of pressure in the tank is greater than the pressure at the entrance of the pump, the liquid in the suction tank is continuously pushed into the pump. According to the suction tube, it is the suction of the pump.

The suction and push process of the pump is a continuous process, creating a continuous flow through the pump.

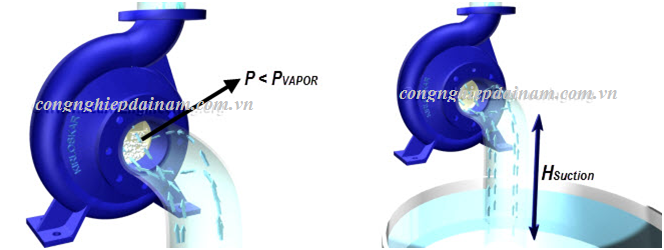

NPSH- How to fix the problem of foaming when pumping

If the pressure on the suction side of the impeller works is lower than the steam pressure of the water, a bad pump phenomenon can occur. The water will start to boil, forming steam bubbles. The bubbles will travel with the flow and will burst in the high pressure area. The bubbles will create a large shock wave after rupture and damage the impeller. This phenomenon is called foaming. The more nozzles, the less pressure on the nozzle side should be created for the water to push up. This fact sets the maximum size limit of the pump head.

H2: Low pressure at the nozzle causes foaming.

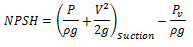

However, foaming can be avoided when you know how to choose a pump. NPSH scores can help us choose a well pumped, non-foaming pump. NPSH score is shown as follows:

P v : Steam pressure.

V: The speed of water at the pump nozzle.

The pump system will have a NPSH point called 'Available NPSH' . The pump manufacturer will specify the minimum NPSH requirement for each pump for safe operation. This is called 'Required NPSH' . If the pump needs to operate without foaming then: